Sublimation printing, also known as “all-over printing,” involves using intense heat to apply designs on materials (fabrics). The designs are printed on sublimation papers using a special hardened sublimation ink which is then converted into a gaseous state and printed onto the material.

Sublimation means turning solid matter into gaseous states without changing into liquid. The design printed on the sublimation paper vaporizes under heat and mixes with the material creating a neat, durable, and fade-free fabric design.

The printing technique is suitable for professional textile designers enticed by the durability and quality of sublimated fabric designs. This article explains the processes involved in sublimation printing. However, let us first understand the two major factors affecting sublimation printing.

The Nature of the Material

You must choose carefully the type of material you want to apply a sublimated design. The sublimation printing method is best for materials in light colors or white, such as polyester apparel. Also, it is suitable for other plastic substrates with polyester coating, cups, mouse pads, etc.

Materials like cotton and dark (or black) colored materials are not advisable when sublimating.

The Digital Printer

You must carefully choose the printer you will use to transfer the designed images onto the sublimation papers. Some printers can be easily used for sublimation purposes and are more suitable than others. An example of a printer usable for sublimation is the Epson Workforce 7720. Several other Inkjet printers are suitable as well.

How Does Sublimation Printing Work?

The sublimation printing process is unique as it employs special methods, different from other textile design-making processes. The ink/design is not placed directly on the material like other textile-making techniques. Instead, the ink is allowed to vaporize and become a part of the fabric.

If you’re thinking about the production process of those beautiful, long-lasting, sublimated graphics on your jersey, below is a step-by-step guide.

Create your Design

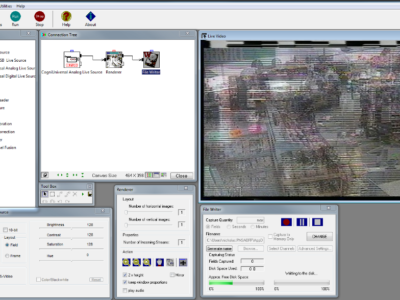

The first thing to do is to create images you intend to sublimate on the fabric. It is best done on a computer (or PC/Laptop) using advanced designer applications and files.

Transfer

Next, you must replicate the designed images onto sublimation transfer paper with sublimation ink. Compatible printers with several features are most suitable for this job.

The liquid ink dries up and solidifies on the paper, reflecting a hard copy of the images designed earlier. Wait till the ink on the paper gets dry before you move on to the next step. The drying process usually takes about 15-30 minutes.

Sublimate

Once you have printed the images onto the sublimation transfer paper, feed it into a heat press (or heated roller) along with the materials. The heat press is where the whole sublimation process takes place.

The heat press operates at an extreme temperature of about 450-500 degrees Fahrenheit. Here, the ink gets so hot that it evaporates and diffuses before it melts. Also, the heat opens the polyester fabric’s pores, allowing the ink vapor to go deeper into the material, mixing with its fibers.

Remove the material from the heat and allow it to cool. This process allows the fabric’s pores to close and capture ink vapor into its fibers.

Conclusion

Sublimation printing is arguably the best printing technique that can be done by pros and beginners alike, provided they have the necessary tools and equipment. With this guide, you can create beautiful, durable, crack-free, innovative, and tech-oriented designs on fabrics!

Comments